Traceability in EAL4+ environment

Orchestra enables standardised data connectivity and traceability in an EAL4+ environment

In the safety-sensitive production areas in which the Smart Meter Gateway is used, the Orchestra low-code data integration platform supports standardised and scalable data connectivity and enables seamless traceability. These features ensure compliance with the high EAL4+ safety requirements and provide Theben with a reliable basis for compliance with and optimisation of safety-critical standards.

Why is seamless traceability in EAL4+ environments so important for Theben AG?

The core issue of standardised data connectivity and traceability in an EAL4+ environment is of central importance to ensure the secure, scalable and flexible integration of production systems and machines. In safety-critical production areas, Orchestra ensures the seamless processing, storage and distribution of data in real time.

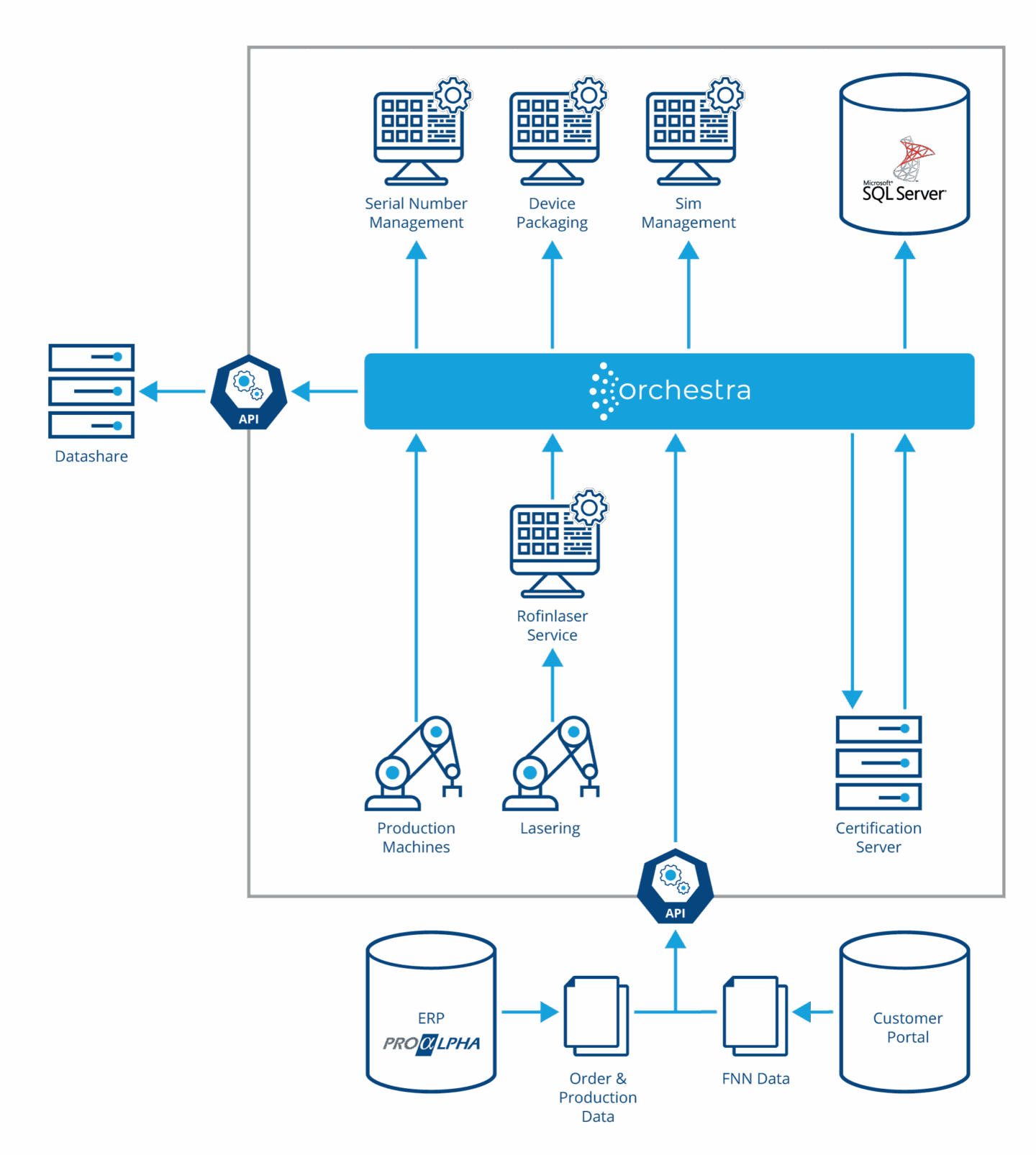

Orchestra has created an API-supported infrastructure based on HTTPS that enables production and measurement data to be retrieved, securely processed, forwarded to other systems and stored at any time without close coupling. All calls are stored centrally and can be traced. In addition to an intermediary level, the infrastructure also offers services to process relevant requirements such as serial numbers and packaging and mobile phone data. These services were created on a modular basis so that they can be reused in other, separate production areas.

Challenges in implementing standardised data connectivity and traceability

- In this certified production environment, no conventional IT systems were available and or separate from existing ERP and ME systems.

- Furthermore, machine and production control as well as quality assurance had to be heavily customised or completely individualised, which led to a highly heterogeneous software landscape.

- The project required agile software development approaches in which complex requirements were to be followed by fast solutions.

- It required seamless traceability of components, including software changes as well as test and measurement values.

What were the requirements for the project?

A key requirement was to connect all relevant systems with each other and enable communication via standardised interfaces. This included both the ERP system outside the certified environment and the applications within the safety-critical area. The system landscape needed to be expandable and flexible in order to meet future requirements.

It was also necessary to ensure seamless traceability of components, including software changes as well as test and measurement values. This required standardised communication with other database systems in order to guarantee the consistency and integrity of the data.

The realisation

All new requirements were either integrated into the existing architecture or designed as a new service. The implementation included a file-based interface from the ERP system for the exchange of order data and the import of customer data via XML files. Order data was exchanged with production machines either via REST web services or as a file exchange. The production data is efficiently imported into an SQL database using REST web services. Finally, a PowerBI dashboard was integrated for production analyses.

Why did you decide in favour of Orchestra?

Thanks to the large number of supported interfaces, formats and protocols, Orchestra can be easily integrated into a wide variety of systems, significantly reducing the amount of resources and time required. The integrated pub/sub model also offers scalability and efficiency, as data can be collected centrally, monitored and distributed as required. This flexibility allows Theben AG to record data such as serial numbers, production parameters and machine statuses consistently and correctly and to make them available for different production areas.

The resulting advantages

By using Orchestra for the translation, mapping and orchestration of data in the context of its NextGen platform, simple system has realised numerous benefits:

Thanks to the wide range of functions and the low-code approach, as a developer I can implement requirements in less time without the need for additional effort for customised integration solutions.

Rica Holzmann