Digitisation of end-to-end processes

Orchestra delivers the right data at the right time for production at MEYER WERFT.

What are end-to-end processes?

End-to-end processes in a manufacturing company encompass all steps along the entire value chain – from the procurement of raw materials to production and delivery of the end product to the customer. These processes also include supporting functions such as warehousing, quality management and logistics, with the aim of ensuring a seamless, efficient and transparent workflow.

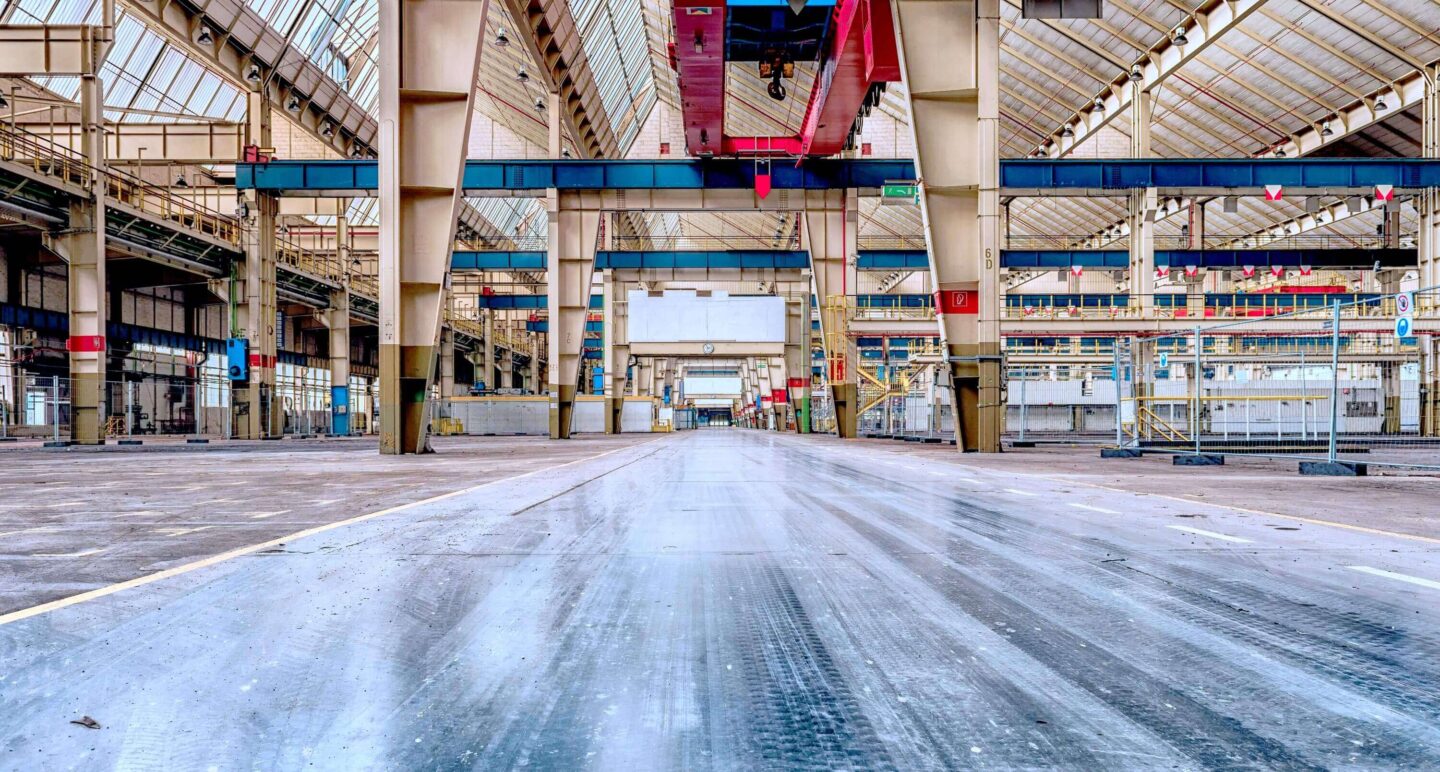

The challenges in production at MEYER WERFT

Within the extensive production and construction halls at MEYER WERFT, it is essential that the appropriate data is available for the individual work and production steps at the various physical stations.

However, various factors make data provision extremely complex:

- At each station, a wide variety of order data must be collated depending on the production step.

- New information is added at each production step, which must be manually recorded and documented (e.g. technical data, order data management, machine data, personnel registrations or data from personnel resource planning).

- The data is delivered to the stations from a wide variety of systems in heterogeneous data formats.

- Different triggers from IT and OT are required for the live display of production data.

Project requirements

New software implemented at MEYER WERFT has proven itself as a central tool for production visualisation. The software requires the efficient provision of critical production data, which is currently provided via specific, highly complex resources. This requires specialised employees to deal with new solutions and complications.

The aim of the collaboration between soffico and MEYER WERFT was therefore to simplify data provision for production overviews using this software and to take the first step towards a digital twin.

The following aspects were important for this:

- Development of a generic approach to data management that can be transferred to other areas of the company.

- A template for data provision developed as part of the generic approach should be reusable in order to offer maximum added value.

- Data logistics should be centrally controlled via the low-code platform Orchestra in order to reduce complexity.

Implementation

To simplify data provision, MES order data, machine data and signals, as well as their visualisations, were combined via Orchestra based on the product to be manufactured.

The resulting advantages:

By implementing Orchestra, MEYER WERFT achieved a number of significant advantages and results that optimised production:

Orchestra is the central piece of the puzzle in our ‘best of breed’ approach and acts as the central data conductor in our smart factory. This brings us a big step closer to our goal of ‘individual standardisation’.

Franziska Wenger