Cloud integration for optimised production processes

Orchestra in closed-loop production at TDK Electronics

Real-time data as the key to mass production

At TDK Electronics AG’s Heidenheim site, the focus is on the mass production of inductors. The production technology department at the site continuously develops and optimises key and core processes for industrial production. The branch also acts as a competence centre for product and process technology.

The handling of production data plays a central role in these optimisation strategies. In the past, valuable data sources – such as test, measurement or image data – were usually available in isolation at the field and control level. The aim of the project was to tap into this previously unused potential of locally isolated data and to automatically optimise production and processes.

In addition, a universal, standardised and scalable data pipeline and platform was to be established.

The challenge:

Data diversity meets network restrictions

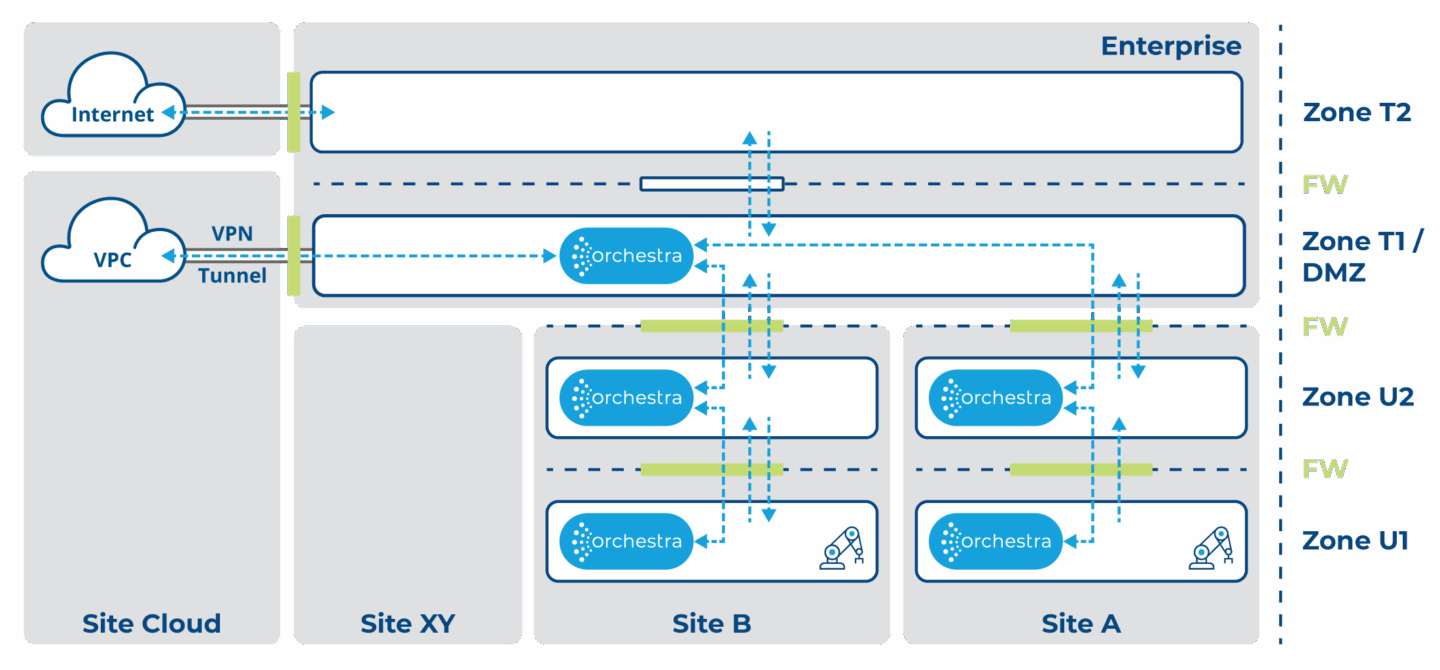

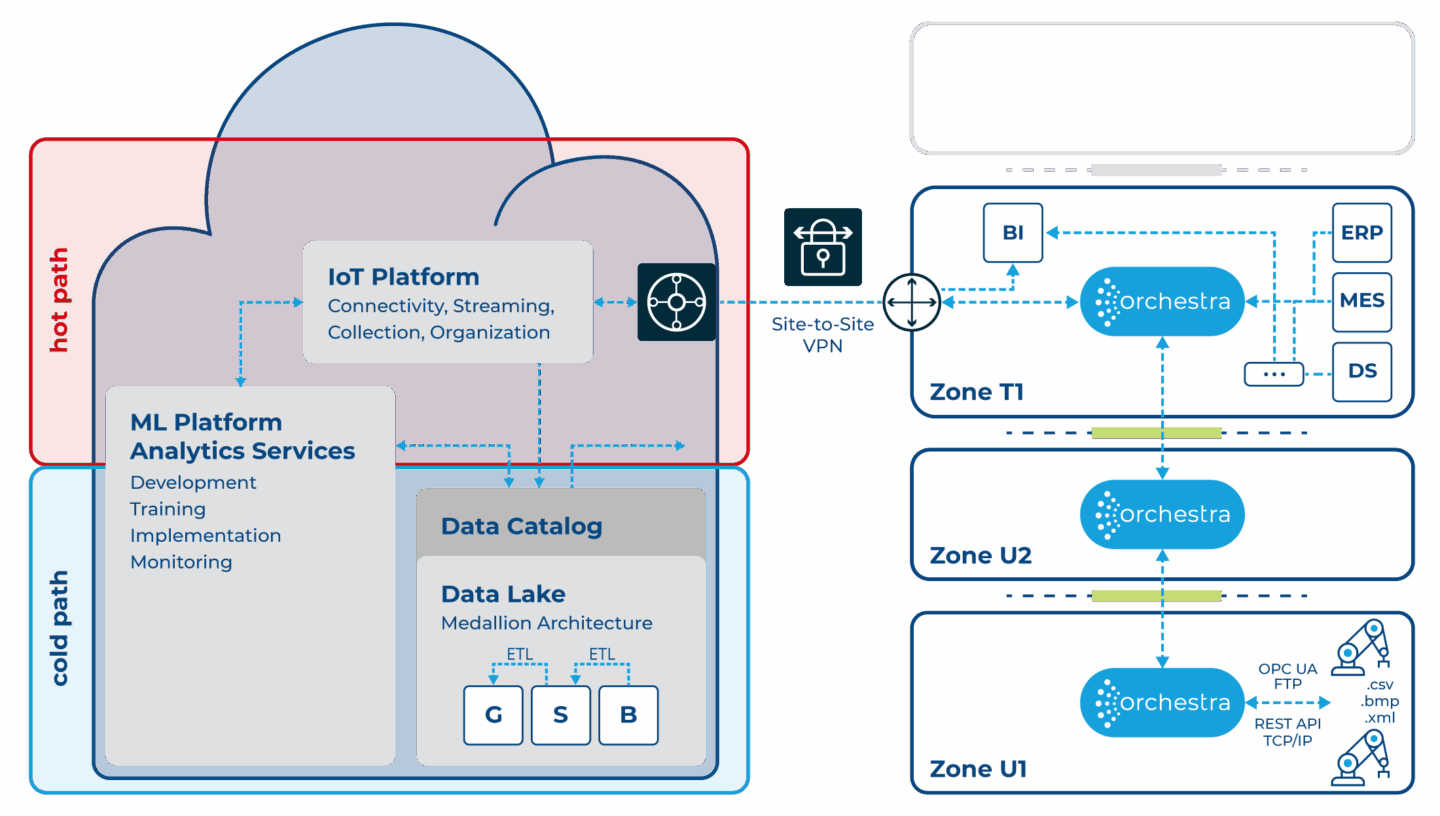

The heterogeneity of the systems used and strict network specifications placed particular demands on the project. A wide variety of data formats and protocols – including XML, CSV, OPC UA, TCP/IP, FTP and REST – had to be taken into account and processed on the source system. Data processing also ran differently with stream processing and batch processing.

High-frequency data streams, such as test and measurement data, as well as image and process data, from various sources came together on a network with clearly defined zone boundaries, in which cloud endpoints were not directly accessible and the use of public endpoints was not permitted.

It was also necessary to enrich the data with contextual information from third-party systems and to secure communication channels – especially between the sensitive network zones.

Despite this complexity, a solution had to be created that was both powerful, scalable and future-proof.

Expectations of the integration solution

Apart from the technical requirements for an integration solution, the team at TDK Electronics AG also had clear expectations as to what results the implementation of an integration solution should deliver:

The process waste should be reduced through direct control of the process result and intelligent control of the process parameters.

Realisation and cooperation

The technical design and implementation of the scenarios was carried out in close collaboration between TDK’s internal project team and the experts from soffico. While basic setups and simple use cases were implemented internally, soffico contributed its expertise for more complex requirements – such as the development of integration logics or the optimisation of communication scenarios.

The shared platform approach with cloud integration creates additional benefits for TDK: Standardised, integrated services can be managed centrally without the need for separate infrastructure management. This enables rapid, modular expansion to include new use cases in the sense of a shared responsibility model.

The solution: Orchestra as a universal data platform

With Orchestra from soffico, TDK opted for middleware that fully fulfils the high technical requirements. The aim was to create a universal, standardised and company-wide data pipeline. The middleware enables the integration of a wide variety of data sources and formats – regardless of the transmission protocol, communication channel or physical location within the infrastructure.

By consistently standardising the communication channel right from the lowest network edge (Zone 1), a scalable integration platform has been created. Point-to-point connections enable targeted protection of the zone boundaries – even under a restrictive ‘deny all’ strategy. At the same time, the integration of new endpoints remains flexible, fast and cost-efficient.

Thanks to Orchestra, we integrate and monitor data from a wide range of interfaces, formats and protocols efficiently, reliably and in real time. This allows us to realise the full value of previously isolated data.

Result: added value through data

Orchestra enables TDK to systematically utilise previously isolated process data – for optimised, automated control of manufacturing processes. The centralised platform increases the value of data along the entire data value chain, reduces process losses and supports data-based decisions in real time.

In addition, the solution found is scalable and can be used across locations and throughout the company.

Sarah Blomeier