Data Monitoring: Monitoring & Quality Assurance

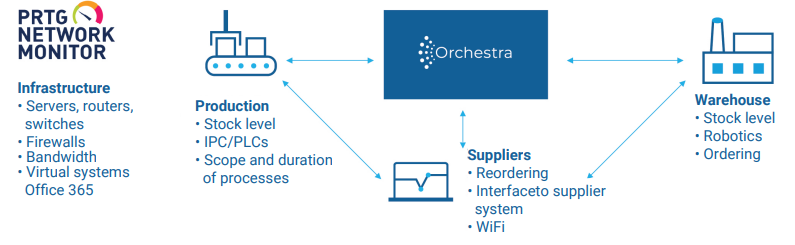

The value chain of Industry 4.0 at a glance

Definition Data Monitoring –

what is Data Monitoring?

Monitoring describes the supervision or observation of data or processes, for example, and thus includes the process of quality assurance in a company. Here, it is first a matter of data acquisition, while controlling or reporting already take care of the management or distribution of the information. Data monitoring is therefore a process in which the quality of the data is proactively checked and evaluated, for example by looking for deviations and – if detected – informing the relevant administrators via an alert so that they can check the error that has occurred.

Why is Data Monitoring so important?

Modern companies and productions face numerous challenges on their way towards Industry 4.0. A functioning operation must now enable the following technical requirements:

- Exchange data across companies within complex IT architectures.

- Immediately detect irregularities or failures and create digital notifications.

- Generate a customized monitoring dashboard easily and reliably.

- Withstand a growing dependency on the availability of IT systems.

- Transparent and flexible communication channels are a much-needed basis for further analysis, quality assurance and process optimization.

Data monitoring now checks for problem areas by detecting deviations or inaccuracies or tracking abnormal behavior. Data is checked for completeness, consistency, correctness, uniqueness and more.

Finally, data monitoring allows production to:

- Know what condition my machine is in.

- Optimization and fine-tuned planning

- Prioritization and optimization of maintenance capacities

Deviations or errors in the data stock can very quickly lead to wrong results in analyses and thus to wrong decisions on the management level. To avoid this, there is data monitoring.

Benefits of Data Monitoring

for your Smart Factory

The implementation of reliable data monitoring brings the following improvements to your production:

Data Monitoring with Orchestra:

A Success Story

When implemented with Paessler, a traceable and secure data exchange is established across company boundaries and between all production facilities and IT systems. Monitoring of all IT components, such as edge devices, networks, cloud environments or IT infrastructure is implemented. It is possible to visualize all relevant data and KPIs in a clear presentation and interactive dashboards. Complex escalation chains can be mapped and targeted notifications and central alerts – on various channels, such as email, push, SMS, MS Teams – can be sent. Transparent monitoring of data transport between IT and OT within heterogeneous industrial environments is ensured by means of flow and packet sniffer sensors.

Digital Quality Assurance:

Why implement Data Monitoring in your own company with soffico & Paessler PRTG?

With Orchestra you build

your own Industrial Suite.

Fully modular and customizable to your IIoT use case.

- Low-code approach thanks to graphical user interface

- Highly scalable through integration of various protocols and formats

- Transparent monitoring of your data flows

Rica Holzmann