Plug & Produce

The successful connecting of proven brownfield and innovative greenfield at SCHOTT AG

The SCHOTT machine landscape

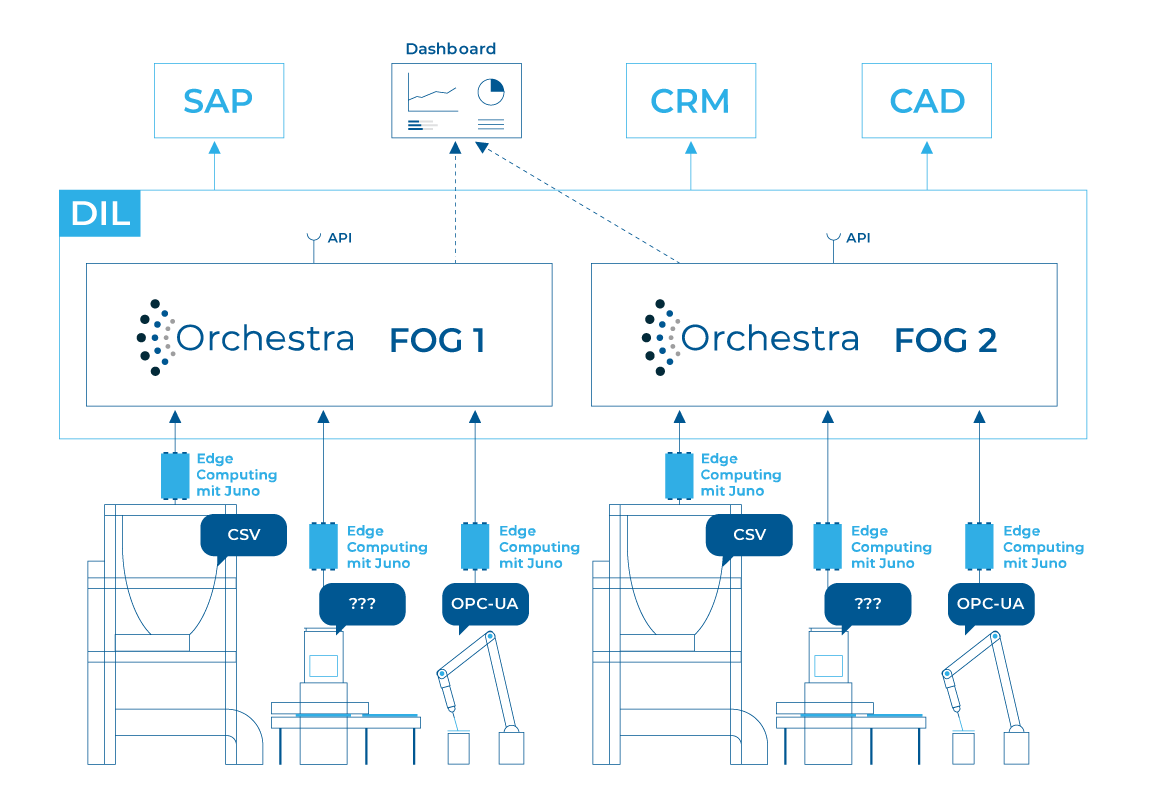

In this brownfield environment which includes machines of various years of construction, QDAS, WCF, data bank, web service, and filebased systems are connected in addition to OPC-UA. The machine-specific protocols and data are transformed into an information model used across the enterprise before being sent to distributed, containerized Orchestra Juno OPC-UA servers.

This information is used to add value by customers, management, production, and IT. In addition, the highest requirements for tamper-proofness and documentation (GMP) in highly regulated industries are met. The implemented edge fog architecture forms the SCHOTT Data Integration Layer (DIL). This layer eliminates redundant data storage and sustainably increases the group-wide data quality. It is easy to use and can be configured in real time without any programming experience. By using publish-andsubscribe mechanisms, this solution is flexibly expandable and scalable for the future.

Challenges at SCHOTT

- Connecting proven Brownfield and innovative Greenfield in growing landscapes.

- Machine data integration efforts are recurring, timeconsuming, individual and complex.

- Many data islands remain and data has to be collected manually.

- Data structures are difficult to interpret and Track & Trace is hard to implement.

- Collecting aggregating and analyzing data requires the collaboration of employees from many departments in one system.

Successful integration of

Greenfield & Brownfield with Orchestra juno

The practical implementation:

edge FOG architecture with Orchestra

In the FOG layer Orchestra provides the data via a uniform communication channel based on the industry standard OPC-UA.

Plug & Produce:

The advantages of connecting to Orchestra

With Orchestra you build

your own Industrial Suite.

Fully modular and customizable to your IIoT use case.

- Low-code approach thanks to graphical user interface

- Highly scalable through integration of various protocols and formats

- Transparent monitoring of your data flows

Sarah Blomeier