Retrofit with INSYS Icom

Connection of decentralized system landscapes

via INSYS Icom and Orchestra juno

What is a retrofit solution?

Retrofit describes the modernization or expansion of existing plants to meet the requirements of Industry 4.0. In detail, this means that a retrofit solution equips existing machines or plants with modern sensor and communication technology. This not only saves costs compared to a new acquisition – retrofitting also enables previously unreadable machine and process data to be recorded, which can be used to ensure maintenance and thus achieve a general process improvement. Modern legal requirements, such as the limits of emission values, can also be met thanks to retrofitting.

Why retrofit – why is the digitization of legacy systems a good solution?

Hardly any company in industrial manufacturing can escape far-reaching digitization in this day and age. Existing legacy systems and brownfield plants play a decisive role here. In most cases, these do not meet the requirements for successful integration into individual IoT use cases. On the one hand, we observe limitations on the hardware side, such as a lack of sensors. On the other hand, however, there is also a lack of data infrastructure and interfaces for the correct forwarding of machine data. This lack of interoperability can be retrofitted to existing machines using the Orchestra retrofit solution.

Advantages, purpose and goals of a retrofit solution – Digitization with Orchestra

Orchestra Success Story:

Retrofit project with our partner INSYS Icom

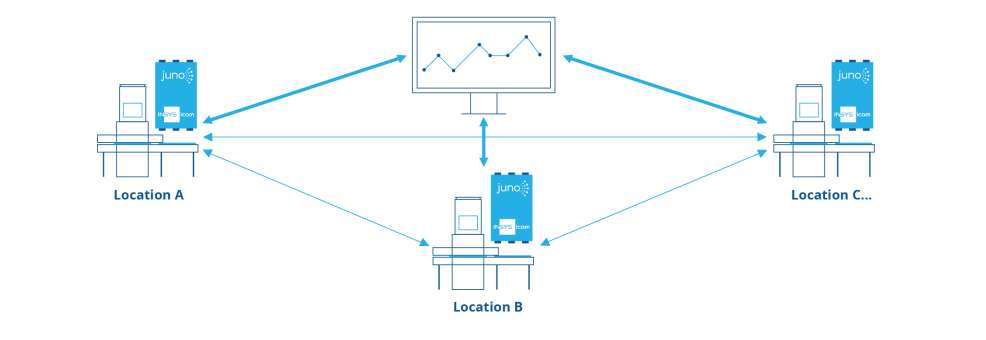

Together with our partner INSYS Icom, a flexible, geographically independent infrastructure was created to network decentralized systems from 150 locations. During the successful retrofit, care was taken to take over existing legacy systems and to convert them to current standards for the new requirements. INSYS Icom is specialized in components and solutions for the secure communication of M2M and IoT applications. The connection of the decentralized system landscapes with the retrofit solution brings numerous digitization advantages:

Practical implementation of the retrofit solution

The implementation was based on the Orchestra juno Plug & Produce concept with the support of the INSYS Icom Gateway and the juno Edge Client. After the roll-out, it was thus possible to use juno as a data buffer in case of network interruptions. The Iiot solution juno thus serves as an intermediate module, a so-called middleware, which maps the data from the old protocol to the new one. The resulting preconfigured solution can quickly and easily preprocess raw data directly at the plant or machine at the respective location, aggregate it and make it available to the communication partners. Local processing and filtered forwarding of data to higher-level systems additionally reduce network traffic. This approach allows machine data to be integrated via standard protocols and makes secure remote maintenance available.

Advantages of the retrofit solution

Secure all the advantages that Industry 4.0 brings for you and your company by retrofitting and modernizing. The retrofit is just one possibility in addition to our many success stories, such as a successful SAP integration or modern data monitoring.

Safe into the future

through variable Retrofit

Fail-safe

through local data buffering

Cost-saving

Through optimization and minimum configuration effort

With Orchestra you build

your own Industrial Suite.

Fully modular and customizable to your IIoT use case.

- Low-code approach thanks to graphical user interface

- Highly scalable through integration of various protocols and formats

- Transparent monitoring of your data flows

Rica Holzmann